BEST IN SHOW

REBRANDING OFFICE ODIDO

By Iwaarden from The Netherlands

This multisite rebranding for Odido, formerly known as T-mobile and Tele2 in the Netherlands featured all manner of visual branding totalling 4,500 square metres of applications. 225 interior locations were dressed with wall graphics, window films, acoustic panels, textile prints, seamless wallpaper, illuminated logos, vinyl graphics, whiteboard, blackboards and printed polyester felt. Digitally printed using HP Latex 800W, Epson 80600, EFI Vutek 5R and FabriVU technologies and laminated and cut with Summa and Zund CAD cutters. The installation was planned over a single weekend with more than 60 skilled signmakers bringing the project to life.

Print Run: 1

Time to Produce: 4 months

DISPLAY AND POP ON PAPER & BOARD

BARBIE @ GRILL’D, THE GALERIES, SYDNEY AUSTRALIA

By Next Printing from Australia

This project allowed the Grill'd burger restaurant in Sydney to be transformed into Dreamburger to promote the launch of the Barbie movie. The production team used Artios CAD, Adobe CC along with Luxien Keyshot to remodel the existing restaurant into a fully immersive Barbie experience. The construction included the use of 13 print materials, mainly using FSC certified Re-Board along with floor graphics and dye sub textiles. Print production involved a combination of UV with Durst P5-350 HS and Oce Colorado UV gel and HP 638 Stitch. The project was cut and finished using Kongsberg and Zund CAD cutting technologies before being fully installed onsite in one night.

Print Run: 1

Time to Produce: 14 Days

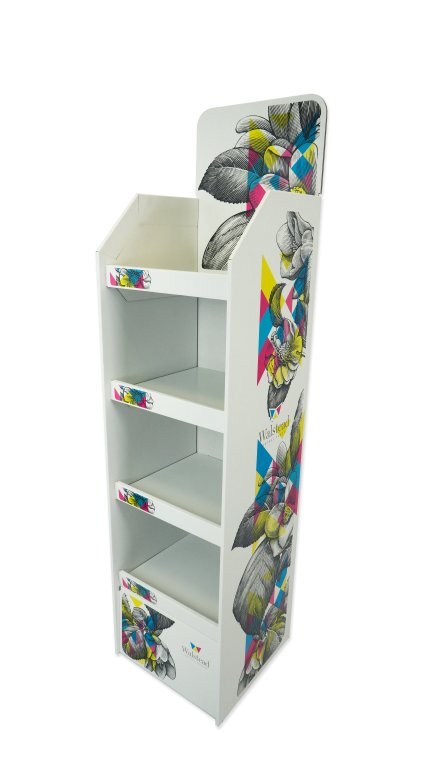

WALSTEAD KRAKÓW

By Ekostand - a biodegradable display from Poland

This POS display has been developed and tested to provide a robost solution with all components being biodegradable. It is manufactured with FSC certified cardboard, printed with GreenGuard certified inks and sustainable fittings. The catches, screws and clear price strips are made from rapidly biodegradable PLA (Polylactic Acid) which is made from plant starch. The final product is the result of 2 years and 9 months of R&D.

Print Run: 4350

Time to Produce: 6 months

CLORALEX WIPES DUMP-BIN

By Colorfast from Mexico

This instore POS dump bin has been digitally printed with Durst technology on b-flute corrugated board. The floor standing display is supplied flat ready-assembled for easy instore activation. A rotational card engineering design creates a solid base to hold products and provide convenient access for consumers.

Print Run: 1000

Time to Produce: 2 weeks

PACKAGING ON PAPER AND BOARD

HACOCOROKO: PUT YOUR HEART INTO THE BOX

By Sakawa Printing Co. from Japan

These personalised gift boxes made on-demand to celebrate family pets or ""UCHINOKO"" contain personalised gifts. The print production using Agfa Jet I MIRA LED UV enabled raised textured personalisation and clear varnish decoration. The E-Flute board was blind embossed and cut to shape using Zund CAD Technology.

Time to Produce: 14 months

TOKYO TSUKIJI ONIGIRI CALENDAR 2025

By Ichikudo Printing Co. from Japan

This refined calendar was inspired by seafood onigiri, the famous Japanese snack. Each month featured its own design, printed 4 colour UV offset with selective screen printed varnish and was blind debossed before die cutting to shape. These components were wrapped in full colour printed textured paper with calendar dates to simulate the nori (seaweed) wrap. This wrap ingeniously incorporated a fold out stand for desk display and the whole package was presented in a 2 colour offset matt varnish presentation box.

Print Run: 2000

Tie to Produce: 1 month

LANCÔME - LUXURY PACKAGING

By La Unión, UILMAC from Mexico

This paper over-board gift pack was printed in full colour on a Heidelberg sheetfed press in 4 colour process on 150gsm coated stock before being matt laminated, UV spot varnished and foil blocked in black. The client required perfect registration of printing techniques and specified no magnets to lock the box. An SBS flap was used to ensure good closure for the box and the internal micro-flute inserts were cleverly designed to hold cosmetic products in a range of complex shapes.

Print Run: 8500

Time to Produce: 4 weeks

DISPLAY AND POP ON PLASTIC

DR. MARTENS X WEDNESDAY - RETAIL DISPLAY

By Imageco from United Kingdom

This Dr Martens x Wednesday retail display project was designed to showcase the unconventional and unashamedly strange for Dr Martens footwear. The store transformation involved the use of printed opal acrylic, display board, black photo frames, MDF plinths finished with concrete spray and clear window vinyl. The printing with swissQprint Nyla 4 flatbed printer enabled the translucent and raised layered print effect. Finished with a top coat of printed varnish to complete the stained glass appearance. The floating books and plinths all supported a mysterious and occult experience that was perfectly delivered.

Print Run: 1

Time to Produce: 3 weeks

TAREE RACETRACK LADBROKES

By Cactus Imaging from Australia

This grey hound racetrack branding required 720m2 of vinyl and 200 sq mtrs of Alupanel. The high coverage red was consistently printed throughout using Durst P5 3.5m hybrid UV printer and sealed with UV coating to double the life of the image. Vinyl was trimmed and finished with kedder rope to fit into a sale track with hot air welder. The whole project was installed within 24 hours.

Print Run: 1

Time to Produce: 11 days

PACKAGING ON PLASTICS

NANOPOUCH

By Nanogruppe from Mexico

This 2kg stand up pouch for premium dry dog food with integrated plastic zip lock and handle was printed digitally on a HP 25000 Indigo Press in soft touch matt finish. Laminated to metalised polyester with selective white used to enhance metallic features where desired. Finished using horizontal pouch making machine.

Print Run: 12000

Time to Produce: 21 days

YELLOW TAXI

By Grupo Mayapack from Mexico

This shrinkable 40 micron PET label was achieved using an Edale FL-3 flexographic process with 8 UV cured colours, providing durability for packaging this motor oil. Once applied to the bottle, the design and production process revealed no significant distortion.

Print Run: 118000

Time to Produce: 6 months

POSTERS

20 YEARS J POINT GROUP PROMOTIONAL POSTERS

By J Point + from Bulgaria

This collection of 8, 48cm x 68cm posters was created to celebrate the 20th anniversary of J Point Group. Each design was printed using a HP Indigo 10,000 B2 digital press onto 250gsm coated stock before being matt laminated. The final process involved multiple passes of raised coloured metallic foil, applied using a Scodix digital foiling machine.

Print Run: 200

Time to Produce: 1 month

SERIGRAPHIES AND FINE ART

INKA SONDORA BY ÃNGELES AGRELA

By Christian M. Walter from Spain

These hand screen printed serigraphs were achieved by printing a background of 6 Lascaux water-based colours for the artist Inka Soñadora. Each of the 16 variants featured different background patterns bringing a total of 24 layers of ink through 100 mesh with custom stochastic screening. All 95cm x 72cm prints on Somerset velvet 300gsm were hand embellished by the artist.

Print Run: 51

Time to Produce: 3 weeks

VERMEER-EDITION BY JAMES FRANCIS GILL

By Graffiti Siebdruck from Germany

This triptych of highly detailed and impactful fine art screen prints by the American pop art painter James Francis Gill are screen printed in 15 colours using direct emulsion on 120T mesh from FM screened colour separations. Printed on Thieme 3020 onto Hahnemühle archival board and hand torn to 66cm x 87cm.

Print Run: 99

Time to Produce: 3 weeks

SECURITY SCREEN-PRINTING HAGIOGRAPHY

By Garden Institute from Greece

This 265mm x 345mm hagiography 90lpi CMYK screen print has been produced on 400gsm Munken Lynx paper. The print has been embellished with phosphorescent "glow in the dark", metallic gold, carbon black and UV fluorescent screen printed inks.

Print Run: 100

Time to Produce: 12 daty

"SIN TITULO" BY AHMED CHERKAOUI

By Christian M. Walter from Spain

This 103cm x 89cm fine art screen print edition by a Morrocan artist born in Boujad has been achieved by hand printing 16 colours onto 300gsm Somerset Radiant White cotton rag paper. The ultra fine FM screening results in smooth transitions and subtle expression and accurate reproduction of the artist's original. Printed with water-based lasceaux screen inks and studio acryl paints through 100T mesh.

Print Run: 90

Time to Produce: 3 weeks

DECALS AND PRINTED LABELS

PREMIUM MEZCAL LABEL

By Moti Digital from Mexico

This project was commissioned by a master distiller from Oaxaca for their artisanal mezcal, Suspiro Mixteco. The labels were digitally printed on HP Indigo 6K Press onto transparent BOPP material and then laminated using the Omega APG system with textured State Label 4 substrate before being printed again by Indigo to the front side. Finished with die cutting to create the window revealing the back side of the label through the bottle.

Print Run: 1000

BOLLYWOOD SUPERSTARS IN PARIS

By Oxysign from France

This 200m Superstars of Bollywood window film installation for the Museé du Quai Branly-Jacques Chirac was printed onto opitcally transparent 3M Scotchcal 8150 vinyl in 5 passes of double sided printing (4 colour process, backed white, light blocking black, white and 4 colour process). The printing was executed using swissQprint Nyla 4 and CAD cut on Zund before comprehensive onsite installation.

Print Run: 1

Time to produce: 4 weeks

DTPL-DEMON

By Decal Tech Private Limited from India

These Tiivra Demon water slide decals were screen printed on a 20 x 30inch sheet on a Stop Cylinder Press in 9 spot colours. These finely detailed designs included coloured metallic special effects to improve visibility of this full face rider's helmet at night whilst adding to its overall aesthetic appeal.

Print Run: 250

Time to Produce: 25 days

WRAPPING

WRAPPING A TELECOM ANTENNA

By ATC Groupe from France

This telecom antenna wrap for Bussy-Saint-Georges supported the integration of this necessary technology into the environment. The design featured a pixelated creative pattern that is interesting to experience and provides camoflage to reduce its visual impact. Digitally printed using EFI technology on ultra resistant Hexis vinyl to wrap the 32m high structure. Installation was completed in sections on the ground before being craned into position on site.

Print Run: 1

Time to Produce: 2 weeks

18 TER 100% BREIZH

By Oxysign from France

This project to wrap 18 trains for BreizhGo in less than a year involves 150m of ultra resistant anti-graffiti self-adhesive film per train. Firstly, each train has to be prepared, cleaned, filled and painted ready for wrapping with Epson printed vinyl and athermic sun protection film. At points 2 trains were wrapped simultaneously.

Print Run: 1

Time to Produce: 3 months

LAMBORGHINI HURACAN STO - INSPIRED BY LEGO

By Wrapstyle from Czech Republic

This wrapping project transformed a Lamborghini Huracan STO into a Lego Technic model. The graphic designer transferred detailing from the Lego model to mimic its appearance through 32 square metres of vinyl printed using an Epson SureColor 80610 Eco Solvent Printer. To further add the impact of this project it was decided to use Avery V4000 reflective and Avery 1105 and DOL 1470z lustre vinyl.

Print Run: 1

Time to Produce: 6 weeks

CREATIVE SPECIAL EFFECT - PAPER, BOARD & PLASTICS

FINE PAPER X SILK SCREEN SAMPLE BOOK & DESIGN INDEX

By Kumazawa Printing Crafts Co from Japan

This special effects showcase brochure was a custom created collaboration between Takeo Paper, Kumazawa Screen Printing and Mori Design to present 39 different special effects achievable using screen printing on creative materials. The grey board binder was screen printed in 2 metallic colours plus neon yellow and contains 5 sections of creative print finishes from flocking to pearlescent to thermochromic techniques amongst the 39 on offer. The printing was achieved on Sakurai cylinder presses, cold foil transfer and offset litho with die cutting, collating, folding and binder assembly. To complete the package a slip case in grey micro flute corrugate was made with a neon yellow core.

A40 GREEN HANGER LANE PROJECT

By Global Erecting Sign Services from United Kingdom

This special print and living wall was created for Blow up Media. It involved an HF welded backlit banner which was surrounded by 6000 living plants with the ability to remove 354 kg of CO2 per year. The planting wall was made up of 2 layers of capillary matting made from recycled clothing that does not rot. It is attached to a waterproof backing board with slits into the outer felt for each plant along with an automatic irrigation system feeding from behind. The resulting hoarding has 150 metres squared of vertical garden and 50 metres squared of printed advertising space.

Print Run: 1

Time to Produce: 2 weeks

VDMB 'LOVES PRINT' ANNUAL MAGAZINE

By Rudolph Druck from Germany

This celebratory annual magazine of the VDMB has been executed with multiple techniques to demonstrate creative precision and excellence in presentation. Using Gmund papers and boards and printed with Canon vario PRINT iX3200 inkjet, foil blocked with Luxor and Colorit foils. Die cut, v-cut and thread sewn bound with inkjet colour edging, glued and assembled by hand with ribbon lift to complete this contemporary reflection of modern print.

Print Run: 800

Time to Produce: 3 weeks

20TH ANNIVERSARY BOOK

By Kanovits Print Atelier from Slovakia

This special effects book is a celebration of 20 years in creative print. At 105mm x 297mm, this unusual format opens out to A4 as a lay flat book. Printed with Xerox Iridesse press using gold, silver, neon pink and opaque white onto black stock to demonstrate creative and engaging potential of special effects. Finished with spot UV on Duplo DuSense, laser cut with SEI Flexi 600 Laser Cutter and Epilog Fusion Pro Laser to complete this showcase.

Print Run: 300

Time to Produce: 1 month

SPECIAL EFFECT ON T-SHIRTS, GARMENTS AND OTHER TEXTILES

PHAYA NAK

By fine rock from Thailand

This all over wrap around, double sided screen printed t-shirt featuring gold foil, puff, silver diamond ink and glow-in-the-dark effects are over printed on discharge plastisol base designs. The vibrant designs join front to back on this outstanding black t-shirt using 45 lpi screen ruling.

Print Run: 5

Time to produce: 1 week

LE RÊVE

By Printex and Digl Design from Russia

This finely detailed screen printed

black shirt design has been reproduced

as a 4 stage grey scale separation.

Printed in 2 tones of grey and white

using 90lpi screen ruling through 120T mesh to achieve smooth gradients. Final frozen ice special effect has been created with structured high build inks.

UNIFORM

By Flexoprom from Russia

This ingenious screen print mimics an image made of masking tape onto dark cotton t-shirt fabric. Printed in 5 colours, 4 of which are Pantone matches on the clear base through 120T mesh at 90lpi and one through 32T mesh with 300 micron high build stencil to achieve raised white.

Print Run: 35

Time to produce: 3 days

PRINTED GARMENTS

A GIRL WITH A TOY

By Flexoprom from Russia

This 6 colour grey scale water-based screen printed t-shirt design was manually printed on a M&R Chameleon 6 colour carousel. Each separation was output at 90lpi and printed through 120T mesh in sequence wet-on-wet with the same water-based grey ink leading to a progressive increase in density where ink layers build on top of each other.

Print Run: 50

Time to Produce: 7 days

BEAUTÉ

By Printex and Digl Design from Russia

This fine resolution screen print with AM separations at 90lpi was printed using an 8 colour automatic Printex Hurricane Carousel. The print sequence with water-based Virus ink was white then white and high white before finishing with clear gel water-based ink through 120T mesh.

ROLL-TO-ROLL PRINTED TEXTILES

LIWA FESTIVAL 2024. AL DHAFRA, ABU DHABI

By Print Works from United Arab Emirates

This creative branding project for the Liwa Village Festival in Abu Dhabi required 16,000 square metres of printed fabrics, 800 flags and 2000 police barriers. The production was split between UV printing and dye sublimation printing, UV was used for the large wall coverings and village perimeter graphics. Dye sublimation was chosen for the flags and the police barriers where stretchable or flowing fabrics were more appropriate.

Print Run: 1

Time to Produce: 30 days

AUTOMATING SPORTSWEAR MANUFACTURING FROM DESIGN TO PRODUCTION

By Nopinz from Israel

This custom printed cyclewear is a perfect representation of textile production on-demand by using Early Vision in Adobe Illustrator making it possible to produce hundreds of metres of customised abrics daily for sewing and dispatch no matter what style, colour or size is requested through e-commerce activation. The production is made with Mimaki inkjet printers and all component parts are cut using Summa laser cutters before making up.

Print Run: ongoing

ROLL TO ROLL PRINT OF MESH FABRIC (IPL)

By Mermain Digital PVT from India

This massive 59,000 square foot circular stadium floor wrap for the opening of the Indian Premier League was printed on mesh fabric using a 3.2m ColorJet Softjet dye sublimation digital printer. All print sections were sewn by 8 tailors using Juki tailoring machines and delivered to the stadium where 40 people unpacked it for installation in the centre of the stadium.

Print Run: 1

Time to Produce: 10 days

GLASS, CERAMIC, METAL AND WOOD PRODUCTS

BARBIE

B Stylographics from United Kingdom

This large scale rainbow floor and wall were printed for the Mattel offices for the film Barbie. Printed with a SwissQ Kudo digital press direct to the reverse of clear polycarbonate achieved this vibrant, colour rich result including the use of neon inks. All panels were tiled and then cut using a Zund iCut to ensure near perfect panel matching.

Print Run: 1

Time to Produce: 5 days

THE WITCHER SEASON 3

By Stylographics from United Kingdom

This complex multicomponent flooring mosaic made for The Witcher season 3 was printed using a Durst P10 HS UV inkjet printer to mimic natural stone including texture that appeared authentic when filmed. The MDF was routed with bevelled edges and installed by the team on set.

Print Run: 1

Time to Produce: 3 days

WICKED

By Stylographics from United Kingdom

This 2m diameter direct to MDF textured wood print was produced to resemble an authentic painting for the film Wicked. Digitally printed using SwissQ Kudo onto 16mm textured MDF in full colour with added surface print texturing. Cut to shape with Zund iCut router.

Print Run: 1

Time to Produce: 3 days

DIRECT PRINTING ON THREE DIMENSIONAL PRODUCTS

SILLA VODKA

By P&P Promotion from Italy

This distinctive, twisted Vodka bottle design has been decorated using the CMCV patented process through which coloured glass frit has been indirectly screen printed using a robotic machine following the contours of the bottle to ensure no distortion of the print. Printed on 2 faces, the fired glass frit is fused.

Print Run: 10000

Time to Produce: 10 month

EXTRAORDINARY FLACONS

By LSINC Corp, and IDS Perfekt from Germany

This set of perfume bottle samples have been decorated on a PeriOne rotary printer using the JET INX ink management system with Marabu Ink. The designs feature 3D structures to mimic glass moulding techniques such as transparent mosiac and pyramidal diamonds with colour graduation fade in between.

Print Run: 300

Time to Produce: 3 weeks

KHAN TI THAM

By Sincerely Screen Co. from Thailand

This Talipot fan used by Buddhist monks in ceremonial rituals has a delicate and refined Kanok pattern. This screen print is created in 3 sections mounted together with a transparent ink between them. A total of 135 printed layers of high build silicone ink result in this delicate and remarkable product.

Print Run: 2

Time to Produce: 60 days

NON PRINTED SIGNAGE

VODAFONE WIMBLEDON

By Stylographics from United Kingdom

This project to celebrate Vodafone's sponsorship of the Wimbledon tennis tournament was to create a giant tennis racket at 7.3m x 4.2m in scale. The racket's shape was CNC cut from high density foam sanded to create a smooth seamless finish. It was then painted in Vodafone's iconic red colour before being ""strung"" with rubber cord to mimic a real tennis racket. The tennis ball in the centre was made from acrylic and then wrapped in fake turf before logos and final letters were added and the sign installed.

Print Run: 1

Time to Produce: 5 weeks

GRAND REX

By Actif Signal from France

To celebrate the 90th anniversary of the world's largest cinema Le Grand Rex in Paris the building received a revitalised façade. The project included the fabrication of the largest rotating illuminated sign in Paris featuring white LED bulbs on a motorised steel structure. Each letter was 2.5m tall. In addtion, a projecting vertical flag sign was affixed to the building measuring 17m with 248 animated red bulbs. Both signs honour the building's historical charm whilst enhancing its visual impact.

Print Run: 1

Time to Produce: 8 months

JOURNEY CAMPUS - WAYFINDING AND ENTRANCE CANOPIES, CAMBRIDGE

By Signbox Limited from United Kingdom

This architectural wayfinding campus signage system featured 3 x 2.75m high beacons, 2 x 6m high entrance totems and 6 building entrance canopies. This sleek and modern system simplified the wayfinding by using fabricated aluminium trays and structures that were laser cut and powder coated. LED lighting and acrylic components were integral to the design as were the graduated black to white fades on the hexagonal material.

Print Run: 1

Time to Produce: 3 months

FUNCTIONAL PRINTING

FASCIAS

By Protolab Electrotechnologies from India

This wheel balancer membrane switch overlay screen printed in 5 colours with 15 passes. Printed with solvent-based inks to surface and subsurface of 500 micron polycarbonate with 60lpi AM screened gradients. Clear LED windows achieved with transparent red ink and glossed surface varnish. Selective application of permanent adhesive and laser cut to size.

Print Run: 400

Time to Produce: 32 hours

PRINTERIORS

REBRANDING OFFICE ODIDO

By Iwaarden from the Netherlands

This multisite rebranding for Odido, formerly known as T-mobile and Tele2 in the Netherlands featured all manner of visual branding totalling 4,500 square metres of applications. 225 interior locations were dressed with wall graphics, window films, acoustic panels, textile prints, seamless wallpaper, illuminated logos, vinyl graphics, whiteboard, blackboards and printed polyester felt. Digitally printed using HP Latex 800W, Epson 80600, EFI Vutek 5R and FabriVU technologies and laminated and cut with Summa and Zund CAD cutters. The installation was planned over a single weekend with more than 60 skilled signmakers bringing the project to life.

Print Run: 1

Time to Produce: 4 months

HIGHFOREST DISPLAY SUITE BY MIRVAC

By ImageBox Group from Australia

The High Forest visitor exhibition centre included a wide range of display graphics including screen printed natural timber panels, 3D laser cut black acrylic with metallic gold faces. Also 3mm ACM, acrylic and self-adhesive vinyl mounted to steel panels printed with SwissQ Nyala 4 with additional clear UV varnish and white ink to create structure and texture in the reproductions of wildlife.

Print Run: 1

Time to Produce: 3 months

THE FIORI HOUSE IN MOSS, NORWAY

By PS Press from Norway

This transformative project for Fiori in Norway was to create an immersive retail identity that reflected an art deco aesthetic. The project extended to the printing, cutting, milling and polishing of a printed polycarbonate ceiling, wall graphics, exterior signage and copper canopy. The centre piece was a fine art reproduction of a swan and the branding was also applied to packaging and labelling in the store. Printed with Canon Colorado M5 and Arizona printers with finishing completed on Zund G3.

Print Run: 1

Time to Produce: 5 months

STUDENT

Heads

By Satyam Sign India from India

This 35cm x 50cm art edition called ""Heads"" was hand screen printed in 5 spot colours with 100T mesh onto 300gsm matt paper. It was reproduced in 2 colourways, 1 in greens and 1 in reds for a final project in Trenčín, Slovakia.

Print Run: 35

Time to Produce: 3 months

⌘E4

By Duale Hochschule Baden-Württemberg from Germany

This '⌘E4' project completed by Fynn Piepenschneider and Max Stümpflen from Mediendesign Ravensburg School under the title 'Chaos and Control' was reproduced using risography. The 8 internal saddle stitched booklets were packaged in a FBB slipcase. The production used fluorescent and spot colours and featured classic risograph imperfection in this contemporary expression of creative print.

Print Run: 200

Time to Produce: 4.5 months

IKONA

By Škola umeleckého priemyslu from Slovakia

Adam Michlovský from the Trenčín School of Art Industry in Slovakia created and screen printed this 7 colour limited edition at 32cm x 50cm. This 'Ikona’ edition was printed on 120T screens on a semi-automatic M&R flat bed with solvent based inks including metallic gold on 300gsm matt Olin paper.

Print Run: 40

Time to Produce: 3 months

INNOVATION

SILLA VODKA

By P&P Promotion from Italy

This distinctive, twisted Vodka bottle design has been decorated using the CMCV patented process through which coloured glass frit has been indirectly screen printed using a robotic machine following the contours of the bottle to ensure no distortion of the print. Printed on 2 faces, the fired glass frit is fused.

Print Run: 10000

Time to Produce: 10 month

PEOPLE'S CHOICE

WALSTEAD KRAKÓW

By Ekostand - a biodegradable display from Poland

This POS display has been developed and tested to provide a robost solution with all components being biodegradable. It is manufactured with FSC certified cardboard, printed with GreenGuard certified inks and sustainable fittings. The catches, screws and clear price strips are made from rapidly biodegradable PLA (Polylactic Acid) which is made from plant starch. The final product is the result of 2 years and 9 months of R&D.

Print Run: 4350

Time to Produce: 6 months

SUSTAINABILITY AWARD

WALSTEAD KRAKÓW

By Ekostand - a biodegradable display from Poland

This POS display has been developed and tested to provide a robost solution with all components being biodegradable. It is manufactured with FSC certified cardboard, printed with GreenGuard certified inks and sustainable fittings. The catches, screws and clear price strips are made from rapidly biodegradable PLA (Polylactic Acid) which is made from plant starch. The final product is the result of 2 years and 9 months of R&D.

Print Run: 4350

Time to Produce: 6 months